Enhancing Fire Safety with Rockwool Sandwich Panels: A Comprehensive Guide

Introduction

Whether it’s a commercial complex, industrial facility, or residential building, architects and builders continually seek innovative solutions to fortify structures against fire hazards. Among these solutions, Rockwool Sandwich Panels emerge as a reliable choice, offering a blend of durability, insulation, and, most importantly, fire resistance. As a leading Rockwool Sandwich Panels manufacturers, Isoflex takes pride in presenting this comprehensive guide to understanding how these panels improve fire safety in buildings.

Choosing the Right Rockwool Sandwich Panels:

Selecting the appropriate Rockwool Sandwich Panels entails considering several crucial factors:

- Fire Performance: Prioritize panels with high fire resistance ratings, conforming to international standards such as ASTM E119 or EN 13501. Look for certifications and test reports validating the fire performance of the panels.

- Thermal Insulation: Besides fire safety, evaluate the thermal insulation properties of the panels. Opt for products offering optimal thermal resistance (R-value) to enhance energy efficiency and indoor comfort.

- Structural Integrity: Ensure the panels exhibit robust structural integrity to withstand external loads and environmental factors. Look for options with durable metal facings and a sturdy core construction.

- Moisture Resistance: Choose panels with moisture-resistant properties to prevent water ingress and subsequent damage, which could compromise fire safety and structural stability.

- Environmental Sustainability: Consider the environmental impact of the panels by assessing their eco-friendly attributes. Look for products manufactured with sustainable practices, such as utilizing recycled materials or employing energy-efficient production processes, to minimize carbon footprint and promote environmental stewardship.

- Compliance with Building Codes and Regulations: Ensure that the Rockwool Sandwich Panels comply with relevant building codes and regulations in your region. Verify that the panels meet fire safety standards mandated by local authorities and regulatory bodies, enhancing legal compliance and ensuring peace of mind.

- Customization Options: Evaluate the customization options available for Rockwool Sandwich Panels to meet specific project requirements. Choose manufacturers offering a variety of panel thicknesses, profiles, colours, and surface finishes to achieve desired aesthetic and functional outcomes while maintaining fire safety standards.

- Installation and Maintenance Considerations: Assess the ease of installation and maintenance associated with the panels. Opt for products that facilitate straightforward installation procedures and require minimal maintenance efforts, thereby reducing labour costs and downtime during construction and building operation phases.

Rockwool Sandwich Panels Manufacturers: Revolutionizing Fire Safety Rockwool Sandwich Panels: What Are They?

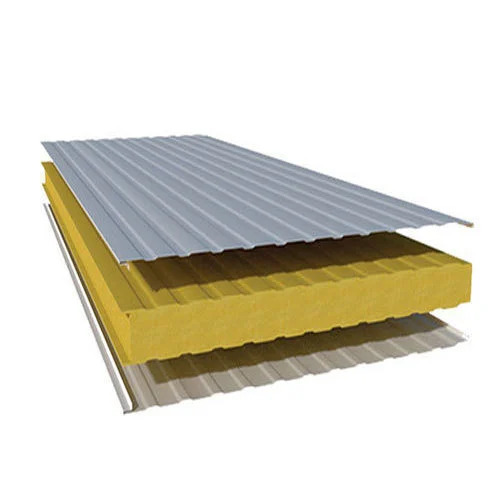

Rockwool Sandwich Panels, also known as mineral wool or stone wool sandwich panels, consist of two outer metal sheets bonded to an inner insulation core made of mineral wool. This core material, derived from volcanic rock or blast furnace slag, lends exceptional fire-resistant properties to the panels. The manufacturing process involves subjecting the raw materials to high temperatures, resulting in dense, non-combustible insulation that effectively retards the spread of flames.

- Benefits of Rockwool Sandwich Panels: Rockwool Sandwich Panels offer a myriad of benefits, making them a preferred choice for architects, builders, and facility managers:

- Exceptional Fire Resistance: The non-combustible mineral wool core provides superior fire resistance, effectively inhibiting the spread of flames and minimizing fire-related damage.

- Thermal Insulation: These panels offer excellent thermal insulation, reducing heat transfer between indoor and outdoor environments. This helps maintain comfortable interior temperatures while lowering energy consumption and utility costs.

- Sound Insulation: In addition to thermal insulation, Rockwool Sandwich Panels exhibit remarkable sound insulation properties, dampening noise transmission and enhancing acoustic comfort within buildings.

- Durability and Longevity: With robust construction and resistance to decay, corrosion, and pests, these panels offer long-term durability, minimizing maintenance requirements and lifecycle costs.

- Sustainability: Rockwool sandwich panels are inherently eco-friendly, as they are manufactured from abundant natural resources. Moreover, their recyclability contributes to sustainable building practices and minimizes environmental impact.

- Enhanced Building Aesthetics: In addition to their functional benefits, Rockwool Sandwich Panels contribute to enhancing the aesthetic appeal of buildings. With a wide range of design options and finishes available, these panels can seamlessly integrate into various architectural styles, elevating the visual appeal of structures while ensuring superior fire protection.

- Improved Indoor Air Quality: Rockwool Sandwich Panels contribute to improving indoor air quality by preventing the growth of mould, mildew, and fungi, which thrive in moist environments. The non-hygroscopic nature of the mineral wool core helps maintain a healthy indoor environment, free from allergens and pollutants, thereby promoting occupant health and well-being.

- Resistance to Pests and Vermin: Unlike traditional insulation materials such as fiberglass or foam, Rockwool Sandwich Panels are inherently resistant to pests, rodents, and insects. This resistance prevents infestations and damage caused by pests, ensuring the longevity and integrity of building structures while upholding fire safety standards.

- Versatility in Application: Rockwool Sandwich Panels offer versatility in application, catering to diverse construction requirements across various sectors. Whether used in exterior walls, roofs, partitions, or ceilings, these panels provide flexible solutions that adapt to different building designs and functional needs without compromising on fire safety performance.

Usage of Rockwool Sandwich Panels in Fire Safety:

The application of Rockwool Sandwich Panels extends across various sectors, playing a pivotal role in enhancing fire safety in buildings:

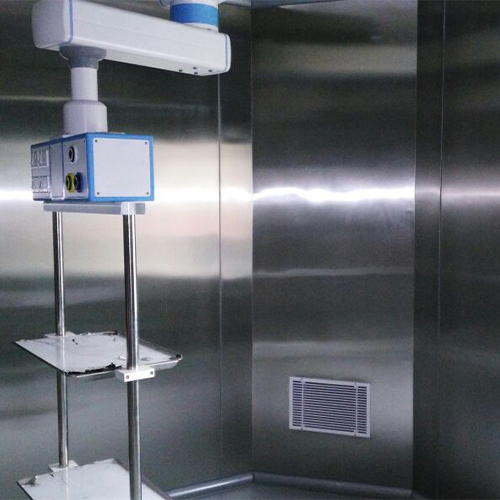

- Commercial Buildings: From shopping malls and office complexes to hotels and restaurants, Rockwool Sandwich Panels are widely used in commercial construction to fortify structures against fire hazards. Their ability to compartmentalize fire and inhibit its spread contributes to occupant safety and property protection.

- Industrial Facilities: Industries such as manufacturing plants, warehouses, and data centers rely on Rockwool Sandwich Panels to safeguard valuable assets and critical operations. The panels’ robust fire resistance and thermal insulation make them indispensable for containing fire outbreaks and minimizing downtime.

- Retrofitting Existing Structures: Rockwool Sandwich Panels are also employed in retrofitting projects aimed at enhancing the fire safety of existing buildings. By installing these panels as cladding or insulation upgrades, older structures can be brought up to contemporary fire safety standards, mitigating risks and extending their service life effectively.

- Hazardous Environments: In environments prone to fire hazards, such as chemical plants, oil refineries, and power stations, Rockwool Sandwich Panels are indispensable for creating fire-resistant enclosures and barriers. Their ability to withstand high temperatures and chemical exposure makes them ideal for safeguarding critical infrastructure and personnel in hazardous industrial settings.

- Transport Infrastructure: Rockwool Sandwich Panels find applications in transport infrastructure projects, including tunnels, bridges, and railway stations, where fire safety is a paramount concern. These panels are utilized to construct fire-resistant enclosures and cladding systems, ensuring the safety of commuters, vehicles, and infrastructure components in case of fire emergencies.

- Transport Infrastructure: Rockwool Sandwich Panels find applications in transport infrastructure projects, including tunnels, bridges, and railway stations, where fire safety is a paramount concern. These panels are utilized to construct fire-resistant enclosures and cladding systems, ensuring the safety of commuters, vehicles, and infrastructure components in case of fire emergencies.

Conclusion

In conclusion, Rockwool sandwich panels stand out as versatile building materials that significantly enhance fire safety. As a reputable Rockwool Sandwich Panels manufacturers, Isoflex remains committed to delivering premium-quality panels that meet the highest standards of performance, durability, and sustainability. By incorporating these panels into construction projects, architects, builders, and facility managers can effectively mitigate fire risks and create safer, more resilient built environments for generations to come.