Maintaining Your Insulated Sliding Doors: Tips and Tricks by Insulated Sliding Doors Manufacturers

Introduction

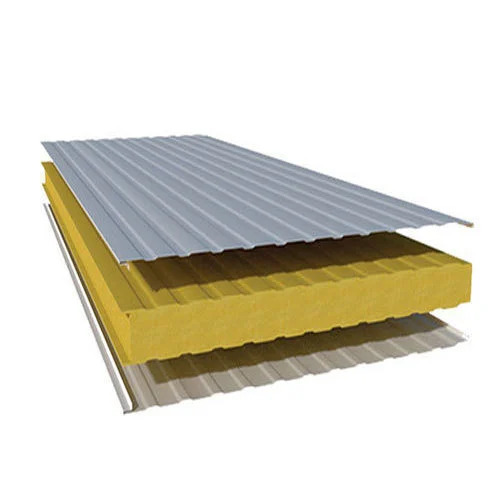

Insulated sliding doors are a popular choice for many modern buildings, providing an excellent balance between aesthetics, energy efficiency, and functionality. Whether you have recently installed insulated sliding doors or have had them for a while, proper maintenance is essential to ensure they perform at their best. In this blog post, we will discuss the importance of maintaining your insulated sliding doors and provide a comprehensive guide to keep them in top-notch condition. We’ll also explore the role of insulated sliding doors manufacturers in ensuring their longevity.

Why Maintenance Matters?

Maintaining your insulated sliding doors is not just about keeping them clean and functional; it’s about preserving the investments you’ve made in your property. Here’s a deeper look at why proper maintenance is crucial.

Energy Efficiency

Insulated sliding doors are known for their energy-efficient properties. They play a vital role in regulating the indoor temperature of your home or building. Properly maintained doors help maintain a consistent temperature, keeping your space warmer in the winter and cooler in the summer. This results in lower energy bills and reduced environmental impact, making them not only cost-effective but also eco-friendly.

Aesthetics and Property Value

Insulated sliding doors are a focal point of your home or building’s exterior and interior design. A well-maintained door enhances the visual appeal of your property, creating a harmonious transition between indoor and outdoor spaces. Neglected doors can become an eyesore and diminish the overall curb appeal. If you plan to sell your property, a well-maintained insulated sliding door can significantly increase its value.

Comfort and Livability

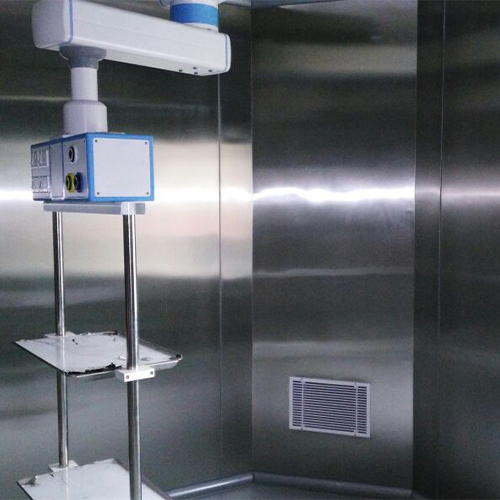

Maintaining insulated sliding doors contributes to the overall comfort and livability of your space. They allow abundant natural light to enter, making rooms more inviting and spacious. Additionally, they provide a seamless connection to outdoor areas, encouraging you to enjoy your surroundings more. When your doors are well-maintained, they function effortlessly, ensuring that you can open and close them with ease.

Security and Safety

One aspect of insulated sliding doors that is sometimes overlooked is their role in security. Proper maintenance ensures that locks, handles, and other hardware components are working well. This means that your doors can continue to serve as a reliable barrier against intruders, enhancing the safety of your property. Moreover, well-maintained doors are less likely to develop operational issues that could lead to accidents or injuries.

Extended Lifespan

Regular maintenance can significantly extend the lifespan of your insulated sliding doors. High-quality doors can last many years, but neglecting maintenance can lead to premature wear and tear. Replacing doors can be a substantial investment, so maintaining them properly is a cost-effective way to ensure their longevity.

Preventing Costly Repairs

Minor maintenance tasks are generally straightforward and cost-effective. However, if you pay attention to these tasks, small issues can escalate into significant problems. For instance, a loose handle or a misaligned track can lead to more extensive and expensive repairs if not addressed promptly. By performing regular maintenance, you can prevent these minor issues from turning into costly repair projects.

Incorporating these points into your understanding of why maintaining insulated sliding doors is essential emphasizes that it’s not just about aesthetics and convenience. It’s about preserving your property’s value, enhancing your comfort, and ensuring the safety and security of your home or building.

What roles do Insulated Sliding Doors Manufacturers have?

Insulated sliding doors manufacturers play a vital role in the performance and longevity of your doors. When selecting a manufacturer, it’s essential to choose one with a good reputation and a history of producing high-quality products. Here are a few key considerations when evaluating manufacturers:

- Quality of Materials: Look for manufacturers that use high-quality materials for their doors, such as robust frames, energy-efficient glass, and durable hardware. Quality materials are the foundation of long-lasting doors.

- Design and Customization: A reputable manufacturer will offer a variety of designs and customization options, allowing you to choose doors that fit your specific needs and preferences.

- Warranty: Check the warranty offered by the manufacturer. A good warranty is a sign of the manufacturer’s confidence in the durability of their product.

- Installation Services: Some manufacturers offer professional installation services. This can ensure that your doors are installed correctly, which is crucial for their long-term performance.

Now that you know the importance of choosing the right manufacturer, let’s move on to the essential maintenance tasks to keep your insulated sliding doors in excellent condition.

Maintenance Tips for Insulated Sliding Doors

- Regular Cleaning: Clean the glass, frames, and tracks of your insulated sliding doors regularly. Use a mild detergent and a soft cloth to clean the glass and a vacuum or a soft brush to remove dirt and debris from the tracks. Rinse thoroughly and dry the surfaces to prevent streaks and water spots.

- Lubricate the Tracks To ensure smooth operation, lubricate the tracks with a silicone-based lubricant. Avoid using oil-based lubricants, as they can attract dirt and cause the tracks to become sticky.

- Check Seals and Weather Stripping : Inspect the seals and weather stripping around the door for any signs of wear or damage.

- Glass Inspection: Inspect the glass for cracks, chips, or condensation between the panes. If you notice any issues, contact the manufacturer for glass replacement or repair.

- Adjust Rollers: If your door is becoming difficult to slide, you may need to adjust the rollers. Consult your manufacturer’s guidelines for specific instructions on adjusting the rollers to maintain smooth operation.

- Regular Painting and Finishing: If your insulated sliding doors have a wooden frame, periodic repainting or refinishing can protect the wood from weather damage and keep it looking great.

- Keep Tracks Clean: Ensure that the tracks remain clear of debris. Debris in the tracks can impede the door’s movement and cause premature wear and tear.

- Secure the Frame: Periodically check the door frame for any signs of movement or misalignment. If you notice any issues, contact a professional installer or the manufacturer for necessary adjustments.

- Consider Professional Inspection: It’s a good idea to have a professional inspect your insulated sliding doors annually, especially if you live in an area with extreme weather conditions. Professionals can identify potential issues early and recommend preventive measures.

Conclusion

Properly maintaining your insulated sliding doors is essential to preserve their functionality, energy efficiency, and aesthetic appeal. By following the maintenance tips provided in this blog, you can ensure that your doors serve you well for years to come.

Remember that choosing a reliable insulated sliding doors manufacturer is the first step in ensuring your doors are high quality and built to last. With the right manufacturer and consistent maintenance, you can enjoy all the benefits that insulated sliding doors have to offer, including reduced energy costs, enhanced security, and a more comfortable living or working environment.