Cold Room Doors Manufacturers: Factors to Consider for Optimal Choice

Introduction

In industrial settings such as food storage facilities, pharmaceutical warehouses, and research laboratories, cold room doors play a pivotal role in maintaining optimal temperatures and preserving the integrity of stored goods. As such, selecting the right cold room doors is crucial for ensuring efficiency, durability, and energy savings. However, by considering key factors and partnering with reputable cold room doors manufacturers like Isoflex, you can streamline the selection process and invest in doors that meet your specific requirements.

Understanding Cold Room Doors

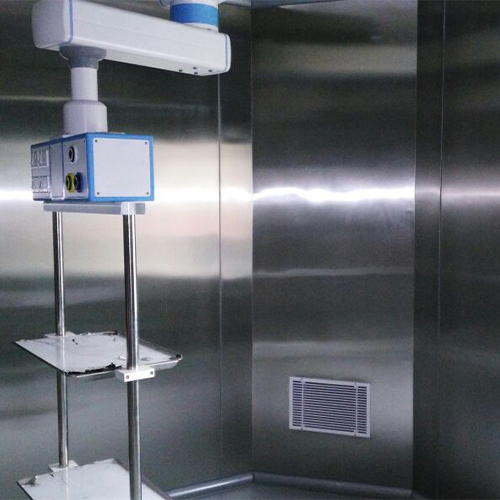

Before delving into the factors to consider when choosing cold room doors, it’s essential to understand their significance and functionality. Cold room doors are specially designed to withstand low temperatures and provide an effective barrier against heat transfer. They are commonly used in walk-in refrigerators, freezers, and climate-controlled storage spaces where precise temperature regulation is essential.

Factors to Consider When Choosing Cold Room Doors Insulation Efficiency:

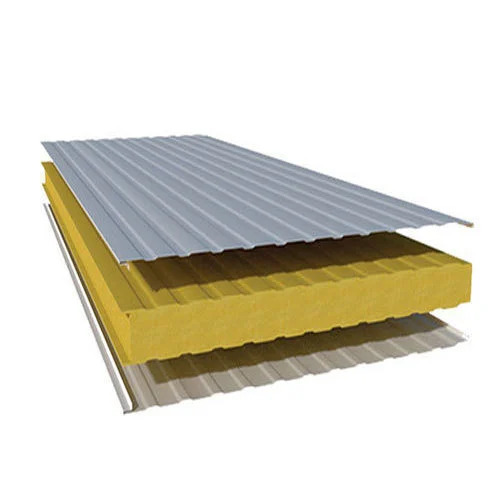

One of the primary functions of cold room doors is to prevent heat exchange between the interior and exterior environments. Therefore, insulation efficiency is paramount. High-quality cold room doors should feature robust insulation materials such as polyurethane foam or expanded polystyrene (EPS) to minimize thermal conductivity. Isoflex excels in this aspect, offering doors with superior insulation properties to ensure optimal temperature control and energy efficiency.

Durability and Structural Integrity:

Cold room doors are subjected to frequent opening and closing cycles, as well as exposure to harsh environmental conditions. As such, durability and structural integrity are non-negotiable factors. Isoflex prioritizes durability by utilizing premium materials and employing advanced manufacturing techniques. Our cold room doors are engineered to withstand heavy usage and maintain their performance even in demanding industrial settings.

Customization Options:

Sealing Mechanism:

Effective sealing is critical for preventing air leakage and maintaining consistent temperatures inside the cold room. Cold room doors should feature robust sealing mechanisms, such as magnetic gaskets or compression seals, to ensure a tight seal when closed. Isoflex integrates advanced sealing technologies into our doors, enhancing their efficiency and performance.

Compliance with Regulatory Standards:

Cold room doors must comply with industry-specific regulations and standards to ensure safety, hygiene, and product integrity. Isoflex adheres to stringent quality control measures and regulatory requirements, certifying our cold room doors for use in food storage, pharmaceutical facilities, and other sensitive environments. Our commitment to compliance underscores our dedication to delivering reliable and compliant solutions to our customers.

Energy Efficiency:

Energy consumption is a significant concern for cold room operators, as excessive energy usage can lead to increased operational costs and environmental impact. Isoflex places a strong emphasis on energy efficiency, designing cold room doors with features such as thermal breaks, insulated panels, and efficient sealing systems to minimize heat loss and reduce energy consumption.

Ease of Maintenance:

Maintenance requirements can impact the overall lifecycle costs of cold room doors. Opting for doors that are easy to clean and maintain can contribute to long-term cost savings and operational efficiency. Isoflex designs our cold room doors with user-friendly features and durable finishes that facilitate hassle-free maintenance and cleaning, ensuring prolonged reliability and performance.

Why Choose Isoflex for Your Cold Room Doors Manufacturers?

As a leading Cold Room Doors Manufacturers, Isoflex stands out for its commitment to quality, innovation, and customer satisfaction. Here’s why Isoflex is your ideal choice for cold room doors:

- Expertise and Experience: With years of industry experience and technical expertise, We have earned a reputation for delivering premium-quality cold room doors tailored to the unique needs of each client.

- Cutting-Edge Technology: Isoflex leverages cutting-edge technology and state-of-the-art manufacturing processes to produce cold room doors that meet the highest standards of performance, durability, and efficiency.

- Customization Capabilities: We offer extensive customization options, allowing clients to personalize their cold room doors to suit specific requirements, preferences, and industry standards.

- Compliance and Certification: Isoflex cold room doors are rigorously tested and certified to comply with relevant industry regulations and standards, ensuring reliability, safety, and peace of mind for our customers.

- Exceptional Customer Support: We are committed to providing exceptional customer support at every stage, from initial consultation and design to installation, maintenance, and after-sales service. Our dedicated team is available to promptly assist clients with any inquiries or technical issues.

- Sustainable Solutions: We are dedicated to sustainability, incorporating eco-friendly materials and energy-efficient designs into our cold room doors to minimize environmental impact and support our clients’ sustainability goals.

- Innovative Design Solutions: Isoflex prides itself on its ability to offer innovative design solutions tailored to the evolving needs of the cold storage industry. Our team of engineers and designers continuously research and develop new technologies and features to enhance the performance, efficiency, and usability of our cold room doors, ensuring that our clients benefit from cutting-edge solutions that set the standard for excellence in the industry.

- Global Reach and Support: With a global presence and network of partners, Isoflex provides comprehensive support and service to clients worldwide. Whether you operate locally or internationally, Isoflex offers seamless logistics, installation, and after-sales support, ensuring a smooth and hassle-free experience at every stage of the project. Our commitment to customer satisfaction transcends geographical boundaries, allowing us to serve clients across diverse industries and regions with unmatched expertise and professionalism.

- Industry-Leading Warranty: Isoflex stands behind the quality and reliability of its cold room doors with an industry-leading warranty. Our doors are built to last, and we back them up with comprehensive warranty coverage to provide our clients with peace of mind and assurance. In the unlikely event of any manufacturing defects or issues, Isoflex is committed to resolving them promptly and efficiently, ensuring minimal disruption to your operations and maximum satisfaction with our products.

- Continuous Improvement and Innovation: Isoflex is dedicated to continuous improvement and innovation, investing in research, development, and feedback-driven improvement processes to stay ahead of industry trends and technological advancements. We actively seek feedback from our clients and partners to identify areas for enhancement and refinement, allowing us to continuously improve our products, processes, and services. By choosing Isoflex, you gain access to a forward-thinking partner committed to delivering value, quality, and innovation for years to come.

Conclusion

Choosing the right cold room doors is a critical decision that can significantly impact the efficiency, performance, and longevity of your cold storage facilities. By considering key factors such as insulation efficiency, durability, customization options, sealing mechanisms, regulatory compliance, energy efficiency, and maintenance requirements, you can make an informed choice that aligns with your specific needs and preferences. Isoflex, as a trusted provider of cold room doors, offers unparalleled quality, reliability, and innovation to meet the demands of diverse industrial applications. Partnering with Isoflex ensures that you receive top-of-the-line cold room doors tailored to your exact requirements, backed by exceptional customer support and a commitment to sustainability. Choose us for your cold room door needs and experience the difference in quality and performance.