Clean Room Doors Manufacturers: Ensuring Contamination Control and Compliance

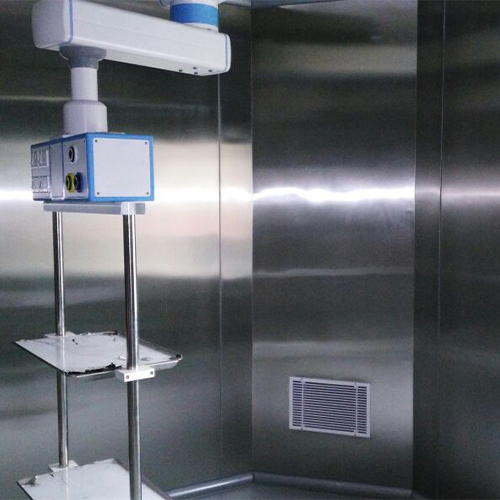

Clean rooms are essential in various industries, such as pharmaceuticals, electronics manufacturing, biotechnology, and aerospace, where maintaining a controlled and contaminant-free environment is paramount. Clean room doors play a crucial role in ensuring the integrity of these controlled environments. This comprehensive guide will delve into the benefits of clean room doors and provide insights on choosing the right ones from reliable Clean Room doors manufacturers.

The Importance of Clean Room Doors

Clean rooms are designed to meet stringent cleanliness and contamination control standards. They are used in industries where even the tiniest particles, microbes, or pollutants can compromise the quality and safety of products or processes. Clean room doors are the gateway to these controlled environments, and their significance cannot be overstated. Here are some key reasons why clean room doors are vital:

- Contaminant Control

Clean room doors act as barriers, preventing the entry of airborne contaminants, dust, and particles from entering the controlled environment. This is critical in pharmaceuticals and electronics manufacturing industries, where even minute contaminants can lead to product defects or health hazards. - Temperature and Humidity Control

Clean rooms often require precise temperature and humidity control. The doors are designed to maintain these controlled conditions, ensuring the environment remains stable and consistent throughout the facility. - Air Pressure Control

In some clean rooms, maintaining specific air pressure differentials is crucial. Clean room doors are constructed to maintain these pressure differentials, preventing unfiltered air from infiltrating the clean area and ensuring that air flows in the desired direction. - Personnel and Equipment Flow

Clean room doors facilitate the movement of personnel and equipment in and out of the clean room while maintaining the required cleanliness levels. They are designed for smooth operation to minimize the risk of contamination during entry and exit. - Compliance with Standards

Industries that rely on clean rooms are often subject to strict regulatory requirements and standards. Clean room doors help facilities meet these standards, ensuring product quality and safety when designed and installed correctly.

Choosing the Right Clean Room Doors

Selecting the appropriate clean room doors for your facility is a crucial decision. The right doors can enhance the effectiveness of your cleanroom while ensuring compliance with industry standards.

- Clean Room Classification

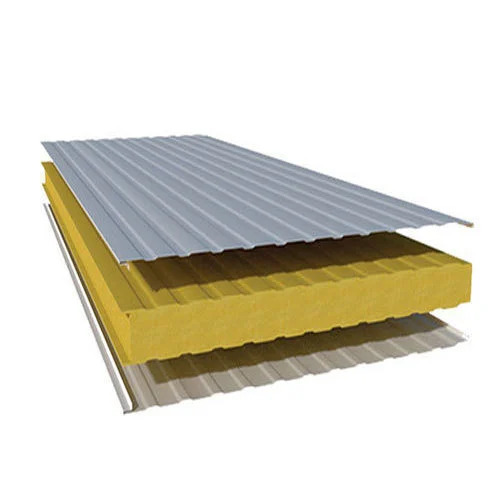

Clean rooms are classified based on their level of cleanliness, typically designated from ISO Class 1 to ISO Class 9, with ISO Class 1 being the cleanest. Different classifications require different levels of contamination control. Ensure the clean room doors you choose are compatible with the required classification. - Material

Clean room doors are typically made from stainless steel, aluminium, or specialized composites. The choice of material should align with the specific needs of your clean room, including its cleanliness requirements, durability, and resistance to chemicals or corrosion. - Door Type

There are various clean room doors, including swinging, sliding, and roll-up doors. The choice of door type depends on factors such as available space, traffic flow, and the need for rapid access. Ensure that the selected door type suits your operational requirements. - Door Seals and Gaskets

Effective seals and gaskets are crucial for maintaining the integrity of a clean room. Ensure that the clean room doors you choose come with high-quality seals and gaskets that create an airtight barrier, preventing contaminants from infiltrating the controlled environment. - Compliance with Standards

Check if the clean room doors meet industry standards and regulations, such as ISO 14644 for clean room classification or any specific guidelines relevant to your industry. Compliance ensures that your facility adheres to quality and safety requirements. - Security Features

Consider the security features required for your clean room. Depending on the nature of your operations, you may need doors with access control systems, electronic locks, or interlocking mechanisms to prevent unauthorized entry. - Maintenance and Cleanability

Clean room doors should be easy to clean and maintain to ensure ongoing performance. Look for doors with smooth, non-porous surfaces that resist microbial growth and are easy to sanitize. - Fire Rating

In some industries, fire-rated clean room doors may be necessary for safety and compliance with building codes. Ensure that the selected doors have the required fire rating, if applicable. - Budget Considerations

Work with Clean Room Doors Manufacturers who can provide options that meet your needs while staying within your budget.

The Benefits of Choosing Reputable Clean Room Doors Manufacturers

When it comes to selecting clean room doors, partnering with a reputable manufacturer is of paramount importance. Here are the benefits of choosing reliable Clean Room Doors Manufacturers:

- Quality Assurance

Reputable manufacturers prioritize quality and adhere to strict quality control processes. This ensures that the clean room doors you receive meet or exceed industry standards, providing reliable contamination control. - Customization Options

Experienced manufacturers can tailor clean room doors to your specific requirements. Whether you need doors of a certain size, material, or design, reputable manufacturers can accommodate your customization needs. - Compliance Expertise

Clean room doors manufacturers with a track record of excellence are well-versed in industry regulations and standards. They can guide selecting doors that meet compliance requirements, reducing the risk of costly mistakes. - Technical Support

Working with a reputable manufacturer means you can access technical expertise and support. They can assist with installation, maintenance, and troubleshooting, ensuring the optimal performance of your cleanroom doors. - Longevity and Durability

High-quality clean room doors from reputable manufacturers are built to last. Investing in durable doors reduces the need for frequent replacements and maintenance, saving you time and money in the long run. - Warranty Protection

Reputable manufacturers often offer warranties on their products. This provides peace of mind, knowing that you are covered in case of any unforeseen issues with your cleanroom doors.

Conclusion

Clean room doors are a fundamental component of controlled environments in various industries. They are crucial in maintaining contamination control, temperature and humidity levels, and air pressure differentials. When choosing clean room doors, it’s essential to consider factors such as clean room classification, material, door type, seals, compliance with standards, security features, and budget.

Partnering with reputable Isoflex Clean Room doors manufacturers ensures you receive high-quality doors that meet your needs and regulatory requirements. We offer quality assurance, customization options, compliance expertise, technical support, and durable products backed by warranties. By making informed choices and collaborating with us, you can ensure the integrity of your clean room and the quality and safety of your products or processes.