Isoflex: Leading Clean Room Doors Manufacturers in India with Unmatched Quality and Innovation

Introduction

In the contemporary world of industrial and commercial spaces, the significance of maintaining optimal conditions cannot be overstated. Whether it pertains to the controlled and sterile environment of a clean room or the meticulously regulated temperature setting of a cold room, the selection of appropriate doors is a pivotal factor in safeguarding the integrity of the contents within. Isoflex, a name synonymous with quality, innovation, and reliability, stands as a pioneering force in the manufacturing of both cold room and Clean Room Doors Manufacturers in India. With an illustrious legacy of excellence coupled with an unwavering commitment to technological advancements, Isoflex continues to redefine and elevate industry standards.

Clean Room Doors Manufacturers: Elevating Hygiene and Sterility

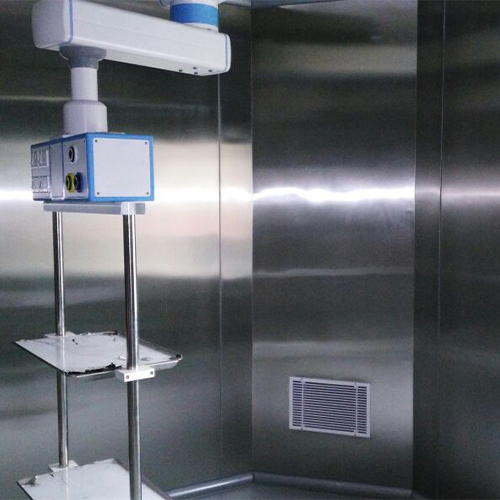

In industries where sterility and contamination control are of paramount importance – such as pharmaceuticals, electronics, and biotechnology – clean room doors assume a critical role. These doors serve as impermeable barriers against pollutants, microbes, and particulates that could compromise the integrity of delicate processes. Isoflex’s clean room doors are meticulously designed to meet and exceed these stringent requirements, offering a seamless blend of functionality, durability, and hygiene.

Isoflex’s clean room doors are not merely products; they are meticulously engineered solutions that reflect a deep understanding of the unique challenges posed by clean room environments. These doors are designed to minimize particulate contamination and facilitate the controlled flow of air within the facility. Constructed using materials that are both easy to clean and resistant to chemicals, Isoflex’s clean room doors provide the highest levels of cleanliness and sterility. With various configurations available – including sliding, swing, and automated options – Isoflex ensures that each clean room’s operational needs are met.

Why Isoflex for Clean Room Doors:

- Unwavering Focus on Hygiene : Isoflex’s clean room doors are meticulously designed to create and maintain the highest levels of hygienic environments, a necessity for industries like pharmaceuticals and biotechnology.

- Technical Expertise in Clean Environments Isoflex’s clean room doors are not just products; they are a result of an in-depth understanding of the stringent requirements of clean room environments, ensuring compliance with industry standards.

- Tailored for Diverse ApplicationsWith a range of cleanroom door configurations available, Isoflex empowers businesses to select the perfect door solution that aligns with their unique operational needs.

- Built for Longevity Isoflex’s clean room doors are engineered for exceptional durability, with materials and construction methods that withstand the rigorous demands of clean room operations.

Cold Room Doors Manufacturers: Forging Ahead with Innovative Temperature Control Solutions

In the realm of cold storage, the importance of cold room doors cannot be emphasized enough. They are the unsung heroes that maintain the desired temperature, uphold the quality of perishable goods, and play an instrumental role in various industries such as pharmaceuticals, food processing, and logistics. Isoflex has etched its name as a leader in this arena, providing cutting-edge solutions that ensure not only the efficiency but also the optimal functionality of cold storage spaces.

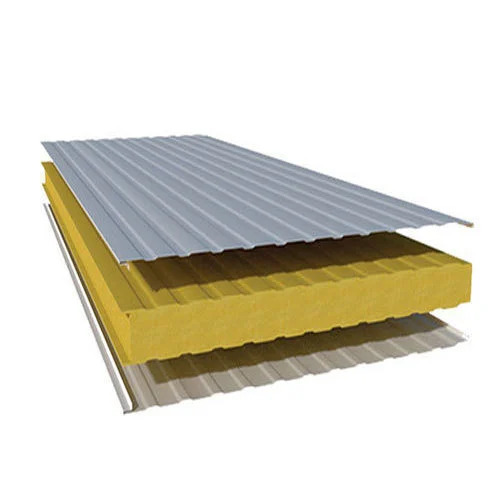

The innovation at the core of Isoflex’s cold room doors is palpable. These doors are engineered with meticulous precision, integrating advanced insulation materials and state-of-the-art sealing mechanisms. The result is a highly efficient barrier against temperature leakage and energy loss, translating into significant cost savings for businesses. Furthermore, Isoflex’s cold room doors are customizable to cater to an array of sizes and specifications, ensuring seamless integration within diverse cold storage infrastructures. Taking sustainability into account, these doors also contribute to the reduction of carbon footprints by minimizing energy consumption – a feature that aligns with Isoflex’s commitment to environmental responsibility.

Why Isoflex for Cold Room Doors:

Insulated sliding doors offer several benefits for industrial facilities, including:

- Innovation at the Forefront Isoflex consistently pushes the boundaries of innovation, continually integrating the latest technologies to enhance the efficiency and overall performance of their cold room doors.

- Tailored Solutions Recognizing the unique nature of each cold storage facility, Isoflex’s doors are meticulously tailored to meet specific requirements, ensuring a perfect fit and optimal performance.

- Energy Efficiency AdvocatesIsoflex’s cold room doors are designed with energy conservation as a guiding principle, offering businesses not only immediate savings but also long-term environmental benefits.

- Quality Assurance Isoflex maintains an unwavering commitment to stringent quality standards, ensuring its cold room doors uphold its reputation even in the most demanding environments.

Unmatched Expertise and a Customer-Centric Approach

The journey of Isoflex towards becoming a premier manufacturer of cold room and clean room doors is marked by an unmatched level of expertise and an unwavering commitment to a customer-centric approach. Backed by a team of highly skilled engineers and industry professionals, Isoflex seamlessly combines technical knowledge with creative solutions to address the distinctive challenges faced by diverse industries.

Isoflex’s commitment to customer satisfaction is not just a tagline; it’s a fundamental principle that resonates throughout every phase of the process, from the initial consultation to the final installation. The dedicated team at Isoflex collaborates closely with clients, taking the time to genuinely understand their needs and requirements. This allows Isoflex to deliver tailored solutions that perfectly align with the client’s objectives and aspirations.

Conclusion

In a rapidly evolving landscape where industries and businesses seek not just efficiency but excellence, Isoflex shines as an emblem of quality and innovation. With a laser focus on innovation, sustainability, and customization, Isoflex stands tall as an industry leader, providing impeccable solutions for temperature control and hygiene that empower businesses across sectors.

As a trailblazer in this field, Isoflex’s commitment to excellence is unwavering and irrefutable. Cold Room Doors Manufacturers and clean room doors transcend the boundaries of mere products; they embody precision engineering, cutting-edge technology, and a steadfast dedication to creating environments that catalyze success. Isoflex’s legacy of innovation and unwavering customer satisfaction firmly solidifies its position as the definitive choice for businesses seeking unparalleled cold room and clean room door solutions in India and beyond. In a world that demands excellence, Isoflex answers the call with doors that signify quality, reliability, and an unrelenting pursuit of perfection.