PUF Sandwich Panels vs. Traditional Insulation Materials: A Comprehensive Comparison from the best PUF Sandwich Panels Manufacturers

Introduction

When choosing the right insulation materials for your construction projects, the options available can be overwhelming. Traditional insulation materials like fiberglass, mineral wool, and polystyrene have been staples in the industry for decades. However, a newer solution, PUF sandwich panels, is increasingly gaining traction for its superior performance and efficiency. At Isoflex, one of the leading PUF Sandwich Panels Manufacturers, we understand the unique advantages of PUF sandwich panels. We are committed to offering top-quality products to meet your insulation needs. In this blog post, we will delve into a detailed comparison of PUF sandwich panels and traditional insulation materials to help you make an informed decision.

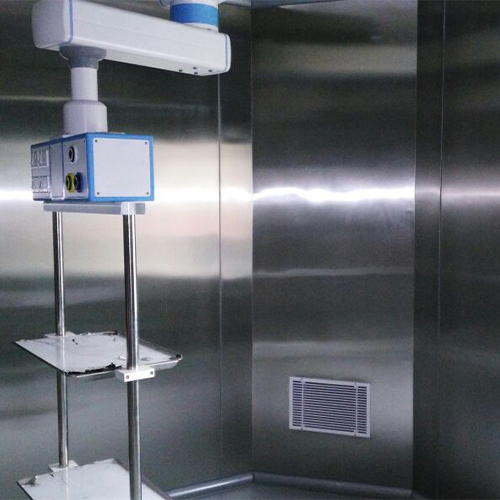

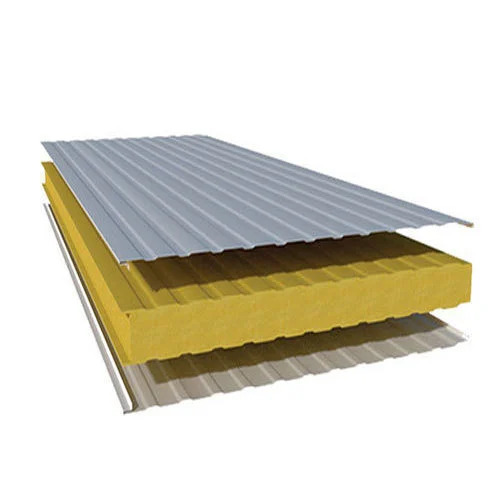

Understanding PUF Sandwich Panels

PUF (Polyurethane Foam) sandwich panels contain three layers: an outer metal skin, an inner metal skin, and a polyurethane foam core. The polyurethane foam core is known for its excellent thermal insulation properties, which significantly enhance the panel’s overall efficiency. These panels are widely used in various applications, including industrial buildings, cold storage facilities, and commercial establishments.

Traditional insulation materials encompass a variety of products, such as:

- Fiberglass Insulation: Made from fine glass fibers, this material is known for its thermal resistance and is commonly used in walls, ceilings, and floors.

- Mineral Wool Insulation: Mineral wool, composed of rock or slag fibers, offers good thermal and acoustic insulation properties.

- Polystyrene Foam (EPS/XPS): Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are plastic materials known for their thermal insulation and moisture resistance.

- Cellulose Insulation: Made from recycled paper products, cellulose is an eco-friendly option with good thermal performance.

Each of these materials has its strengths and limitations, but PUF sandwich panels offer a range of benefits that can surpass traditional options in several key aspects.

Thermal Insulation Performance

PUF Sandwich Panels

One of the most significant advantages of PUF sandwich panels is their superior thermal insulation performance. The polyurethane foam core in PUF panels provides an excellent R-value, measuring the panel’s heat flow resistance. With a low thermal conductivity of around 0.022 to 0.028 W/m·K, PUF panels help maintain consistent indoor temperatures, leading to substantial energy savings over time.

Traditional Insulation Materials

While traditional materials like fiberglass and mineral wool offer decent insulation, they often fall short compared to PUF panels. For instance, fiberglass typically has an R-value of 2.2 to 2.7 per inch, while PUF panels can achieve an R-value of 4.0 to 6.0 per inch of thickness. This means that PUF panels are more efficient at reducing heat transfer, making them a more effective solution for temperature control.

Moisture Resistance

PUF Sandwich Panels

Due to the closed-cell structure of the polyurethane foam, PUF sandwich panels are inherently resistant to moisture. This resistance prevents the absorption of water, which can otherwise lead to mould growth and deterioration over time. The metal skins on both sides of the panel also add an extra layer of protection against water ingress.

Traditional Insulation Materials

Traditional materials vary in their moisture resistance. For example, fiberglass and cellulose are prone to moisture absorption, which can compromise their insulation effectiveness and lead to potential health risks due to mold. While polystyrene foam is moisture-resistant, it doesn’t match the overall performance of PUF panels in extreme conditions.

Structural Integrity and Durability

PUF Sandwich Panels

PUF sandwich panels are known for their robust structural integrity and durability. The combination of metal skins and polyurethane foam core offers a strong, stable solution for building envelopes. These panels resist impacts, making them suitable for applications where durability is a primary concern.

Traditional Insulation Materials

While materials like mineral wool and fiberglass offer good thermal and acoustic insulation, they are generally not used as standalone building components due to their lack of structural strength. They are often combined with other materials to achieve the desired performance, which can add to the overall cost and complexity of the project.

Installation Efficiency

PUF Sandwich Panels

PUF sandwich panels are designed for quick and efficient installation. Their prefabricated nature means they can easily assemble on-site with minimal labour and time. This efficiency translates into lower installation costs and faster project completion times.

Traditional Insulation Materials

The installation of traditional insulation materials can be more labour-intensive and time-consuming. For instance, fiberglass and mineral wool require careful handling and installation to achieve the best results, which can lead to higher labor costs and extended project timelines.

Environmental Impact

PUF Sandwich Panels

At Isoflex, we are committed to environmental sustainability. PUF sandwich panels can be manufactured using eco-friendly processes, and their energy efficiency helps reduce overall energy consumption, contributing to lower greenhouse gas emissions. Additionally, the longevity of PUF panels means they have a longer life cycle, which can reduce the need for frequent replacements.

Traditional Insulation Materials

Traditional insulation materials vary in their environmental impact. While cellulose insulation is made from recycled materials, others like fiberglass and polystyrene can have significant environmental footprints due to their manufacturing processes and disposal challenges.

Why Choose Isoflex as Your PUF Sandwich Panels Manufacturers?

As one of the premier PUF Sandwich Panels Manufacturers, Isoflex is dedicated to delivering high-quality products that meet our clients’ diverse needs. We take pride in our state-of-the-art manufacturing processes, ensuring that every panel we produce adheres to the highest performance and durability standards.

Our team of experts is always ready to assist you in selecting the best insulation solutions for your specific requirements. We offer a range of PUF sandwich panels designed for various applications, and our commitment to customer satisfaction means that you can trust us to provide the best products and services in the industry.

Conclusion

When compared to traditional insulation materials, PUF sandwich panels offer superior thermal performance, moisture resistance, structural integrity, and installation efficiency. While traditional materials have their place in the insulation market, PUF sandwich panels stand out as a modern and effective solution for a wide range of construction needs.

At Isoflex, we are proud to be a leading name among PUF Sandwich Panels Manufacturers. Our commitment to quality, sustainability, and customer satisfaction makes us the ideal partner for your next project. Explore our range of PUF sandwich panels and experience the benefits of advanced insulation technology.