Cold Room Doors Manufacturers: Factors to Consider for Optimal Choice

Introduction

In the ever-evolving world of food safety and storage, the role of cold room panels cannot be overstated. These innovative solutions are more than just building materials—they are essential components in the infrastructure that help businesses meet stringent food safety regulations. At Isoflex, one of the leading cold room panels manufacturers, we understand the critical role that these panels play in ensuring that food products remain fresh, safe, and compliant with regulatory standards. In this blog, we will explore how cold room panels help businesses adhere to food safety regulations and how Isoflex’s products are designed to meet these needs effectively.

Understanding Cold Room Panels

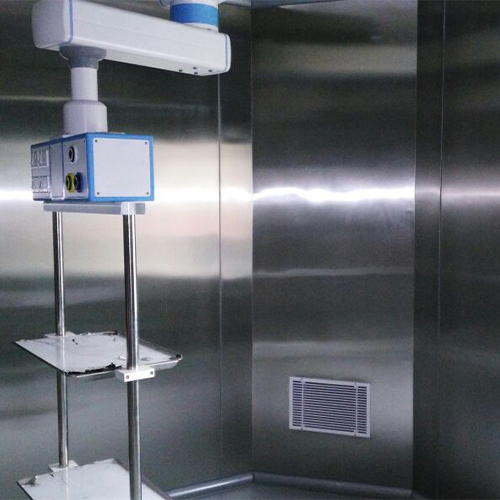

Before delving into the specifics of how cold room panels support food safety, it’s important to understand what they are and how they work. Cold room panels are insulated panels used in the construction of cold storage facilities, such as walk-in refrigerators, freezers, and chilled storage areas. These panels are designed to maintain low temperatures, creating a stable environment for the storage of perishable goods.

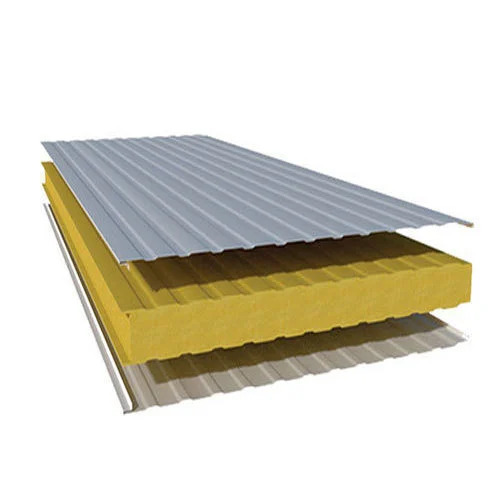

The core of a cold room panel typically consists of a high-performance insulation material encased in metal sheets, which can be made from materials like galvanized steel, stainless steel, or aluminium. This construction not only helps in achieving thermal efficiency but also ensures durability and ease of maintenance.

The Role of Cold Room Panels in Food Safety

Food safety is a multi-faceted issue encompassing various practices and regulations. One of the fundamental principles of food safety is the proper storage of food to prevent contamination and spoilage. Here’s how cold room panels help in achieving compliance with food safety regulations:

Temperature Control

Maintaining the correct temperature is crucial for food safety. According to regulations from food safety authorities such as the USDA and FDA, food products must be stored at specific temperatures to prevent bacterial growth and spoilage. Cold room panels help achieve and maintain these temperatures by providing superior insulation. The high R-value of our panels, a key metric of thermal resistance, ensures that the desired temperature is consistently maintained, which is essential for preserving the quality of food products.

Hygienic Design

Food storage areas must be designed to be clean and resistant to contaminants. Isoflex’s cold room panels feature smooth, non-porous surfaces that are easy to clean and disinfect. This design helps maintain high hygiene standards, which is crucial for compliance with food safety regulations. Our panels are manufactured to have minimal seams and joints, reducing the risk of contamination and making cleaning more straightforward.

Durability and Structural Integrity

Food storage environments can be demanding, with constant temperature, humidity, and heavy usage changes. Isoflex’s cold room panels are designed to withstand these conditions while maintaining their insulating properties. Our panels are crafted from high-quality materials that resist damage from impacts and abrasions, ensuring that the cold storage environment remains effective and compliant with safety standards over time.

Energy Efficiency

Energy efficiency is a key consideration in food storage regulations. Efficient energy use not only reduces operational costs but also supports environmental sustainability. Isoflex’s cold room panels are designed with advanced insulation technologies that minimize energy loss. By enhancing the energy efficiency of cold storage facilities, our panels help businesses meet environmental regulations and reduce their carbon footprint.

Compliance with Standards and Regulations

Food safety regulations are governed by various standards, including those set by local, national, and international bodies. Isoflex is committed to ensuring that our cold room panels meet or exceed these standards. Our panels are manufactured in compliance with ISO standards and other relevant regulations, which assures our clients that they are investing in products that support their efforts to comply with food safety laws.

Why Choose Isoflex as Your Cold Room Panels Manufacturers?

As one of the leading cold room panels manufacturers, Isoflex is dedicated to providing products that meet and exceed industry standards. Here’s why you should choose us for your cold room panel needs:

Innovative Solutions

At Isoflex, we pride ourselves on offering innovative solutions that address the evolving needs of the food storage industry. Our cold room panels are designed with cutting-edge technology to provide superior insulation, durability, and energy efficiency.

Commitment to Quality

Quality is at the heart of everything we do. We use only the highest-grade materials and adhere to strict manufacturing processes to ensure that our cold room panels deliver consistent performance and long-term reliability.

Customer-Centric Approach

We understand that every business has unique requirements. Our team works closely with clients to provide customized solutions that fit their needs, ensuring they get the best products for their cold storage facilities.

Comprehensive Support

From initial consultation to post-installation support, Isoflex is here to assist you. We offer expert advice, detailed product information, and ongoing support to help you maximise our cold room panels.

Proven Track Record

With years of experience in the industry, Isoflex has built a reputation for excellence. Our products are used by diverse clients, from small businesses to large corporations, who trust us to provide reliable and effective cold room panel solutions.

Conclusion

Cold room panels are essential for maintaining food safety and complying with storage regulations. Their role in temperature control, hygienic design, durability, and energy efficiency makes them a cornerstone of effective food storage practices. At Isoflex, we are proud to be at the forefront of the cold room panel industry, offering high-quality products that help businesses meet their food safety and storage goals.

If you’re looking for a trusted partner in the cold room panel industry, look no further than Isoflex. As leading cold room panels manufacturers, we are committed to providing innovative, high-quality solutions that support your food safety efforts and help you achieve regulatory compliance. Contact us today to learn more about our products and how we can assist you in creating a safe and efficient cold storage environment.