Choosing the Right PUF Sandwich Panels Manufacturer: Why Isoflex is Your Best Choice?

When selecting the perfect PUF (Polyurethane Foam) sandwich panels manufacturer for your construction or insulation needs, making the right choice is crucial. PUF sandwich panels are known for their excellent thermal insulation properties, durability, and versatility, making them a popular choice in various industries. However, not all PUF Sandwich panels manufacturers are created equal, and choosing the wrong one can led to subpar products and project delays.

This comprehensive guide will explore the key factors you should consider when selecting a PUF sandwich panel manufacturer. We will highlight why Isoflex is ideal for your PUF sandwich panel requirements. With a strong reputation for quality and innovation, Isoflex stands out as a leading manufacturer in the industry.

Understanding PUF Sandwich Panels

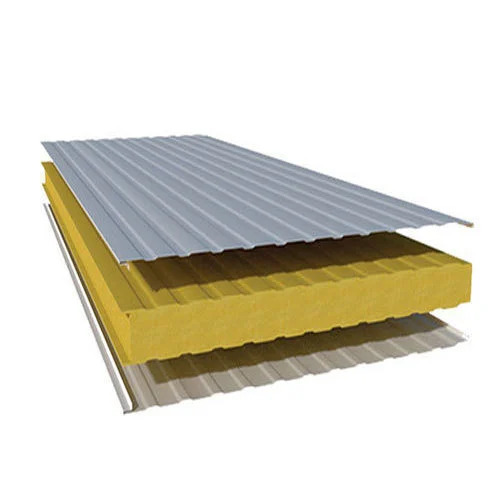

Before delving into the process of choosing the right PUF sandwich panels manufacturer, it’s essential to have a solid understanding of what PUF sandwich panels are and why they are in high demand.PUF sandwich panels have three layers: two outer metal sheets (typically steel or aluminium) and a polyurethane foam core layer. These panels are widely used in construction for their exceptional insulation properties, lightweight nature, and ease of installation. They offer an ideal solution for temperature-sensitive environments, making them suitable for cold storage facilities, commercial buildings, industrial structures, and more applications.

Key Considerations When Choosing a PUF Sandwich Panels Manufacturer

Selecting the right PUF sandwich panels manufacturers is a critical decision that can significantly impact the success of your project. Here are some essential factors to consider:

Quality Assurance

Look for a manufacturer with a proven track record of producing high-quality PUF sandwich panels.

Experience and Expertise

Consider the manufacturer’s experience in the industry. An established manufacturer will likely have the expertise to meet your specific requirements.

Customization Options

Depending on your project’s unique needs, you may require customized PUF sandwich panels. Ensure that the manufacturer can accommodate custom specifications.

Manufacturing Capacity

Assess the manufacturer’s production capacity to determine if they can meet your project’s volume and timeline requirements.

Sustainability

Consider a manufacturer’s commitment to sustainability and eco-friendly production processes in today’s environmentally conscious world.

Why Isoflex Stands Out as Your Best Choice?

Now that we’ve covered the essential considerations, let’s explore why Isoflex is the ideal PUF sandwich panels manufacturers for your needs.

Unmatched Quality Assurance

At Isoflex, quality is our top priority. We adhere to strict quality control processes and have earned various certifications that reflect our commitment to excellence. Our PUF sandwich panels are tested rigorously to ensure they meet or exceed industry standards, guaranteeing an exceptionally performing product.

Decades of Experience

With decades of experience in the industry, Isoflex has a deep understanding of PUF sandwich panel manufacturing. Our seasoned experts have honed their skills over the years, enabling us to provide solutions catering to various applications and project complexities.

Customization Expertise

Isoflex offers extensive customization options, allowing you to tailor our PUF sandwich panels to your project’s specifications. We can deliver panels with unique dimensions, coatings, or insulation properties if you need.

State-of-the-Art Manufacturing Facilities

Our modern manufacturing facilities have cutting-edge technology and machinery, ensuring efficient production and consistent quality. Isoflex can handle small and large-scale projects, delivering on time and within budget.

Competitive Pricing

While we prioritize quality, Isoflex offers competitive pricing that aligns with your budget constraints. We believe in providing value for your investment by delivering top-notch PUF sandwich panels at affordable rates.

Eco-Friendly Practices

Isoflex is committed to sustainability. Our manufacturing processes are designed to minimize environmental impact, making our PUF sandwich panels an eco-friendly choice for your projects. We believe in building a greener future while meeting your insulation needs.

Isoflex’s Wide Range of PUF Sandwich Panel Applications –

One of the reasons why Isoflex is the best PUF sandwich panels manufacturers is our panels’ versatility.

- Cold Storage: Isoflex PUF sandwich panels provide exceptional insulation, maintain temperature control, and preserve perishable goods’ freshness in cold storage facilities.

- Commercial Buildings: Our panels are used extensively in commercial construction, offering energy efficiency and structural integrity.

- Industrial Facilities: Isoflex panels are well-suited for industrial structures, providing insulation, fire resistance, and durability.

- Agriculture: Farms and agricultural facilities benefit from our PUF sandwich panels for maintaining controlled environments and efficient operations.

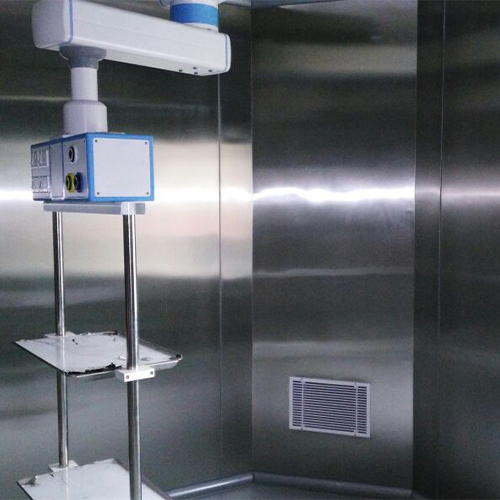

- Clean Rooms: Isoflex panels are an excellent choice for clean rooms, ensuring a sterile and contamination-free environment.

In conclusion, Isoflex is the unrivalled choice for PUF sandwich panels manufacturers. Our unwavering commitment to excellence and dedication to meeting your unique project needs sets us apart in the industry.

We understand that selecting the right PUF sandwich panel manufacturer is not a decision to be taken lightly. Your project’s success hinges on the quality and performance of your chosen materials, and Isoflex is here to ensure your success.

A relentless pursuit of perfection has marked our journey in the industry. We consistently strive to exceed industry standards, pushing the boundaries of what PUF sandwich panels can achieve. Whether you require panels for construction, cold storage, or industrial facilities, Isoflex delivers solutions that offer thermal insulation, soundproofing, and structural integrity that are second to none.

At Isoflex, we believe in collaboration. We see ourselves as your partners in progress, working closely with you to understand your project’s unique requirements. We take pride in offering a wide range of customization options, enabling you to tailor our PUF sandwich panels precisely to your specifications. Your vision becomes our mission, and we are dedicated to bringing that vision to life.

Top-notch quality should come at a manageable cost. Isoflex delivers affordability without compromising the uncompromising quality we are known for.

Environmental responsibility is another cornerstone of Isoflex’s philosophy. We are deeply committed to sustainability and the preservation of our planet. Our PUF sandwich panels are not only highly efficient but also eco-friendly. By choosing Isoflex, you contribute to a greener and more sustainable future.

The trust of our satisfied customers speaks volumes about the Isoflex difference. Their testimonials and continued business testify to the reliability and excellence we bring to every project. We value these long-lasting partnerships and continue to work tirelessly to earn your trust with every panel we manufacture.

Choosing Isoflex as your PUF sandwich panel manufacturer means choosing the assurance of quality, the expertise of industry leaders, the flexibility of customization, and the benefits of sustainability. We take pride in being the manufacturer that consistently delivers on its promises, ensuring that your project is built on a foundation of excellence.

Your project is not just another job for us; it’s a chance to showcase our commitment to quality and innovation. Contact us today to discuss your project requirements and experience firsthand why Isoflex is the trusted name in PUF sandwich panels.