Environmental Sustainability in the Cold Room Panels Manufacturers: A Comprehensive Guide

Introduction

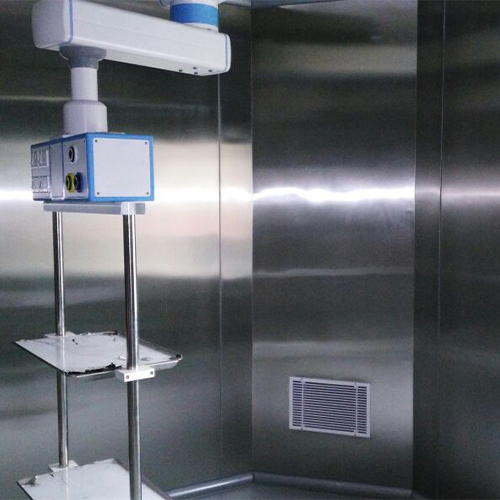

The construction sector, in particular, is under scrutiny for its carbon footprint and environmental impact. One area of focus within construction is the manufacturing and utilizing of cold room panels. These panels are integral to various industries, such as food storage, pharmaceuticals, and logistics. In this comprehensive guide, we delve into the environmental implications of cold room panels, shedding light on their eco-friendliness and the efforts of Cold Room Panels Manufacturers, to mitigate their environmental footprint.

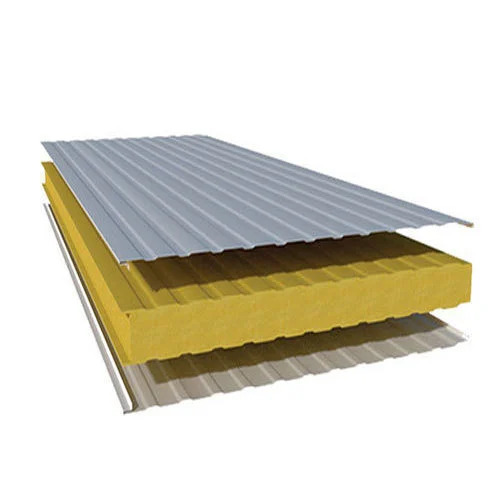

Before delving into their environmental impact, it’s crucial to understand cold room panels and their significance. Cold room panels are prefabricated structural elements for constructing temperature-controlled environments such as cold storage facilities, walk-in freezers, and refrigerated warehouses. They are composed of metal, foam insulation, and sometimes composites and provide thermal insulation and structural integrity.

Environmental Impact Assessment

Resource Extraction and Manufacturing ProcessesCold room panels are manufactured through resource extraction, energy consumption, and emissions. For instance, the production of metal panels entails mining ores, smelting, and shaping, all of which have significant environmental ramifications. Similarly, insulation foam is manufactured using petrochemicals and energy-intensive processes.

Energy Efficiency and Operational Impact

While cold room panels are designed to provide efficient insulation, their energy efficiency during operation is crucial in assessing their environmental impact. Well-insulated cold storage facilities can reduce refrigeration and cooling systems’ energy consumption and greenhouse gas emissions. However, efficient design or proper installation can lead to energy wastage, offsetting potential environmental benefits.

Lifecycle Analysis

A comprehensive environmental assessment considers cold room panels’ entire lifecycle, from raw material extraction to end-of-life disposal or recycling. Factors such as durability, maintenance requirements, and recyclability provide insights into their long-term environmental impact. Sustainable practices, such as using recycled materials or designing panels for disassembly and reuse, can mitigate environmental burdens..

Waste Generation and Disposal

Disposing of cold room panels at the end of their service life presents challenges due to their composite nature. Improper disposal can lead to landfilling or incineration, contributing to pollution and resource depletion. Manufacturers play a crucial role in implementing take-back programs, p

The Role of Cold Room Panel Manufacturers

Manufacturers are pivotal in shaping the environmental footprint of cold room panels. Through innovation, research, and sustainable practices, they can enhance the eco-friendliness of their products and contribute to a greener future. Here are some initiatives undertaken by leading manufacturers:

Manufacturers are increasingly opting for eco-friendly materials, such as recycled metal and bio-based insulation foams, to reduce the environmental impact of cold room panels. Optimizing panel designs for minimal material usage without compromising performance can further enhance sustainability.

Implementing energy-efficient manufacturing processes, such as using renewable energy sources and optimizing production workflows, can reduce carbon emissions and resource consumption during panel fabrication.

Manufacturers are investing in research and development to improve the recyclability of cold room panels and establish take-back programs to facilitate responsible disposal and recycling at the end of their lifecycles.

The production of cold room panels involves several resource-intensive processes. This includes mining raw materials such as iron ore, aluminium, or steel for metal panels, followed by energy-intensive processes like smelting and shaping. These processes emit greenhouse gases and other pollutants, contributing to environmental degradation.

Similarly, insulation foam, a critical component of cold room panels, is manufactured using petrochemicals derived from fossil fuels. This contributes to carbon emissions and raises concerns about the depletion of finite resources and pollution associated with petrochemical extraction and processing.

Furthermore, the transportation of raw materials to manufacturing facilities adds to cold room panels’ carbon footprint. Long-distance transportation via trucks, ships, or trains increases energy consumption and emissions, particularly if fossil fuels power these modes of transportation.

Cold room panels are designed to provide efficient insulation, significantly reducing energy consumption while operating temperature-controlled facilities. Properly insulated buildings require less energy to maintain desired temperature levels, lowering greenhouse gas emissions and reducing reliance on fossil fuel-based energy sources.

However, the energy efficiency of cold room panels depends not only on their design and quality but also on factors such as installation techniques and maintenance practices. Poorly installed panels or inadequate maintenance can compromise insulation effectiveness, leading to increased energy consumption and environmental impact over the lifecycle of the building.

Moreover, choosing refrigeration and cooling systems used with cold room panels also influences energy efficiency. Energy-efficient systems, powered by renewable energy sources where possible, can further reduce the environmental footprint of temperature-controlled facilities.

A comprehensive lifecycle analysis of cold room panels considers various stages, including raw material extraction, manufacturing, transportation, installation, operation, maintenance, and end-of-life disposal or recycling. Assessing environmental impacts at each stage provides insights into the overall sustainability of cold room panel systems and identifies opportunities for improvement.

Durability is a critical factor in the lifecycle analysis of cold room panels. Panels that withstand environmental stressors and mechanical forces are less likely to require frequent replacement, reducing resource consumption and waste generation over time.

Additionally, maintenance requirements influence the environmental footprint of cold room panels. Regular maintenance, including inspections, repairs, and cleaning, ensures optimal performance and extends the panels’ lifespan, thereby minimizing the need for premature replacement and associated environmental impacts.

Recyclability is another important consideration in lifecycle analysis. Cold room panels that can be easily disassembled and recycled at the end of their service life reduce the demand for virgin materials and mitigate waste generation. Manufacturers are increasingly exploring innovative recycling technologies and implementing take-back programs to facilitate recycling old panels.

Due to their composite nature, disposing of cold room panels at the end of their service life poses significant environmental challenges. Traditional disposal methods, such as landfilling or incineration, can result in pollution, resource depletion, and greenhouse gas emissions.

To address this issue, manufacturers actively explore alternative disposal methods and promote recycling initiatives. Recycling cold room panels conserves valuable resources and reduces the environmental burden associated with landfilling or incineration.

Moreover, manufacturers are increasingly adopting circular economy principles, prioritizing the reuse, refurbishment, and recycling of materials and products at the end of their lifecycle. This shift towards a circular approach aims to minimizewaste generation and maximize resource efficiency, thereby reducing the environmental impact of cold room panels.

Conclusion

In conclusion, while cold room panels are vital in supporting industries reliant on temperature-controlled environments, their environmental impact cannot be overlooked. However,Cold Room Panels Manufacturers can minimize their ecological footprint through innovation, research, and sustainable practices and contribute to a greener future.

Manufacturers can enhance the eco-friendliness of cold room panels by prioritizing material selection and optimization, implementing energy-efficient production processes, and investing in lifecycle considerations and recycling programs. Industry can pave the way towards eco-friendly solutions that benefit businesses and the planet with concerted efforts.

As consumers and stakeholders increasingly prioritize environmental sustainability, the role of manufacturers in driving positive change becomes ever more crucial. By embracing innovation and sustainability, manufacturers can ensure that cold room panels become an environmentally friendly solution for temperature-controlled environments worldwide.