PUF Sandwich Panels Manufacturers: Revolutionizing Energy Efficiency in Buildings

Introduction

In the quest for sustainable construction solutions, PUF (Polyurethane Foam) Sandwich Panels have emerged as a game-changer, revolutionizing the way buildings are designed for energy efficiency. These panels offer a perfect amalgamation of structural integrity, insulation properties, and ease of installation. In this comprehensive guide, we delve into the realm of PUF Sandwich Panels, exploring their significance, selection criteria, and their profound impact on enhancing energy efficiency in buildings.

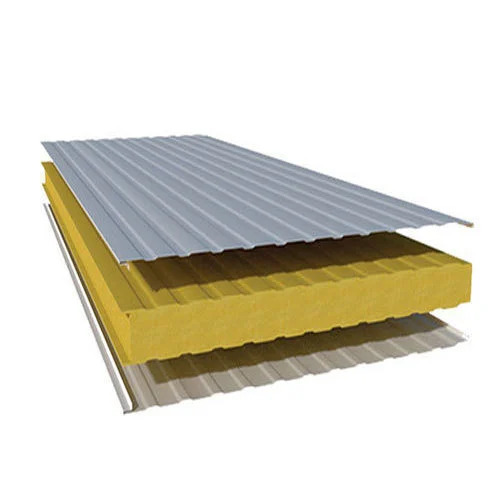

PUF Sandwich Panels, also known as Polyurethane Foam Sandwich Panels, consist of three layers: a core made of polyurethane foam sandwiched between two layers of metal sheets. This construction not only provides exceptional strength but also ensures superior insulation properties, making them ideal for a wide range of applications in the construction industry.

These panels are manufactured by PUF Sandwich Panels Manufacturers using advanced techniques, ensuring precision and quality in every panel produced. The manufacturing process involves injecting polyurethane foam between the metal sheets under controlled conditions, resulting in panels that are lightweight yet robust, and highly resistant to environmental factors such as moisture, heat, and corrosion.

Choosing the Right PUF Sandwich Panels Manufacturers:-

Selecting the appropriate PUF Sandwich Panels is crucial to achieving optimal energy efficiency in buildings. Here are some key factors to consider when choosing PUF Sandwich Panels:

Thermal Performance: Look for panels with high R-values, indicating better thermal insulation properties. PUF Sandwich Panels offer excellent thermal insulation, minimizing heat transfer and reducing the need for artificial heating and cooling.

Structural Strength: Ensure that the panels meet the required structural standards to withstand the loads imposed by the building. PUF Sandwich Panels are renowned for their exceptional strength-to-weight ratio, providing structural stability while reducing the overall weight of the building.

- Fire Resistance: Opt for panels with fire-resistant properties to enhance the safety of the building occupants. PUF Sandwich Panels are available with fire-rated cores, offering enhanced fire resistance and compliance with building regulations.

- Durability: Choose panels that are durable and resistant to environmental degradation. PUF Sandwich Panels are inherently resistant to moisture, corrosion, and pests, ensuring long-term performance and minimal maintenance requirements.

- Customization Options: Consider panels that can be customized to suit specific design requirements and aesthetic preferences. PUF Sandwich Panels Manufacturers offer a variety of options in terms of thickness, coatings, colours, and profiles, allowing architects and builders to achieve their desired architectural vision.

- Environmental Impact: Consider the environmental impact of the panels, including their manufacturing process, recyclability, and potential for reusability. Opting for PUF Sandwich Panels that are manufactured using sustainable practices and can be recycled at the end of their lifespan contributes to overall environmental stewardship.

- Acoustic Performance: Evaluate the acoustic properties of the panels, especially if the building is located in a noisy environment or requires sound insulation. PUF Sandwich Panels with enhanced acoustic performance help reduce noise transmission, creating a more comfortable and productive indoor environment.

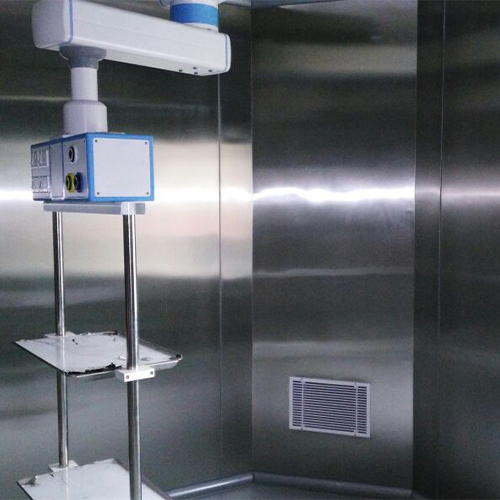

- Compatibility with Building Systems: Ensure compatibility with other building systems such as HVAC, electrical, and plumbing. PUF Sandwich Panels that integrate seamlessly with these systems streamline the construction process and minimize potential conflicts during installation, resulting in a more efficient building envelope.

- Resistance to Impact and Vandalism: Assess the panels’ resistance to impact and vandalism, particularly in high-traffic areas or public spaces. PUF Sandwich Panels with durable coatings and robust construction offer enhanced protection against damage, extending the lifespan of the building envelope and reducing maintenance costs.

- Warranty and Support: Choosing PUF Sandwich Panels from reputable manufacturers who offer comprehensive warranties and technical assistance ensures peace of mind and long-term satisfaction with the product.

Benefits of PUF Sandwich Panels for Energy Efficiency:

PUF Sandwich Panels offer a multitude of benefits that contribute to enhancing energy efficiency in buildings:

- Superior Insulation: The core of polyurethane foam provides exceptional thermal insulation, minimizing heat transfer through the building envelope. This helps in maintaining comfortable indoor temperatures year-round, reducing the reliance on heating and cooling systems and thereby lowering energy consumption.

- Air Tightness: PUF Sandwich Panels create a tight seal when installed properly, minimizing air leakage and preventing thermal bridging. This improves the overall energy performance of the building by reducing heat loss or gain through cracks and gaps in the structure.

- Reduced Energy Costs: By effectively controlling thermal conductivity and minimizing energy losses, PUF Sandwich Panels help in reducing energy consumption for heating and cooling, resulting in significant cost savings over the lifetime of the building.

- Sustainable Construction: PUF Sandwich Panels are environmentally friendly, as they are manufactured using eco-friendly processes and materials. Additionally, their superior insulation properties contribute to lower greenhouse gas emissions by reducing the carbon footprint associated with building operations.

- Fast Installation: PUF Sandwich Panels are prefabricated off-site and can be quickly installed on-site, reducing construction time and labour costs. This accelerated construction process further enhances energy efficiency by minimizing on-site energy consumption and disruptions.

- Moisture Management: PUF Sandwich Panels effectively manage moisture infiltration and condensation within the building envelope, preventing mould growth and preserving indoor air quality. This moisture resistance contributes to the longevity of the building materials and reduces the risk of structural deterioration.

- Enhanced Comfort: By maintaining consistent indoor temperatures and minimizing drafts, PUF Sandwich Panels create a more comfortable and productive indoor environment for occupants. This leads to improved occupant satisfaction, higher productivity levels, and reduced absenteeism in commercial and residential buildings.

- Compliance with Energy Codes: PUF sandwich panels help achieve compliance with energy codes and standards by improving the overall energy performance of buildings. This ensures that the building meets regulatory requirements and qualifies for incentives and rebates associated with energy-efficient construction practices.

- Adaptability to Climate Conditions: PUF Sandwich Panels are versatile and adaptable to various climate conditions, providing effective insulation in both hot and cold climates. This adaptability allows for the construction of energy-efficient buildings in diverse geographical regions, optimizing thermal comfort and energy savings year-round.

- Future-Proofing: Investing in PUF Sandwich Panels future-proofs the building against rising energy costs and evolving regulatory requirements. By prioritizing energy efficiency and sustainability, building owners and developers can safeguard their investments and ensure long-term viability in an increasingly eco-conscious market.

Conclusion

In conclusion, PUF Sandwich Panels offer a holistic solution for enhancing energy efficiency in buildings, providing superior insulation, structural strength, and durability. As leading PUF Sandwich Panels Manufacturers to innovate and refine their products, the adoption of these panels is expected to grow exponentially in the construction industry. By choosing the right PUF Sandwich Panels and incorporating them into building designs, architects and builders can create sustainable and energy-efficient structures that benefit both the environment and the occupants.