Maintaining Consistent Temperatures in Storage Facilities: The Essential Role of Cold Room Doors Manufacturers

Introduction

When it comes to maintaining precise temperature conditions in storage facilities, every detail matters. One crucial component that often goes unnoticed is the cold room door. These specialized doors are integral to ensuring that the internal environment of cold rooms, freezers, and other temperature-controlled spaces remains stable and efficient. At Isoflex, we understand the significance of this component in the cold storage industry. As leading Cold Room Doors Manufacturers, we are committed to providing solutions that meet the highest standards of quality and performance. In this blog post, we’ll explore how cold room doors help maintain consistent temperatures and why choosing the right manufacturer can make all the difference.

Understanding the Importance of Temperature Consistency

Temperature consistency is not just a matter of comfort but a critical aspect of product preservation and energy efficiency. In storage facilities, especially those handling perishable goods or sensitive materials, maintaining the correct temperature can be the difference between quality and spoilage, efficiency and waste. Cold room doors play a central role in achieving and maintaining these optimal conditions.

How Cold Room Doors Maintain Temperature Consistency?

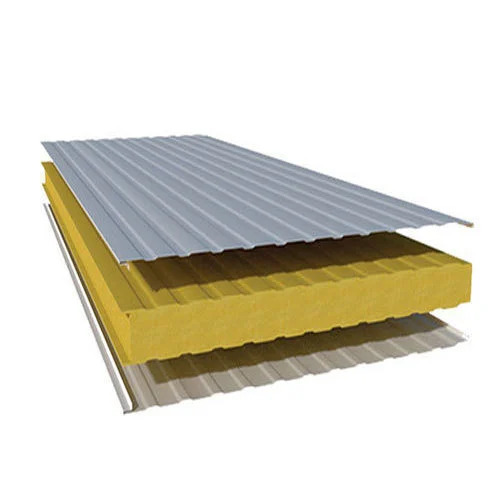

Thermal Insulation

One of the primary functions of cold room doors is to provide effective thermal insulation. High-quality cold room doors are designed with advanced insulation materials, such as polyurethane foam, which has a low thermal conductivity. This means that these doors can significantly reduce the rate of heat transfer between the cold room and the external environment.

At Isoflex, we use state-of-the-art insulation technology in our products. Our doors are designed to keep the cold air in and the warm air out, which helps maintain the desired temperature inside the storage facility. The better the insulation, the less energy is required to keep the room at the correct temperature, leading to lower energy costs and a more sustainable operation.

Seamless Sealing

Another crucial feature of cold room doors is their ability to create a tight seal when closed. Gaps, cracks, or poor sealing can lead to significant temperature fluctuations and energy losses. Our cold room doors come with high-performance gaskets and seals that ensure a perfect fit every time the door is closed. This tight seal prevents cold air from escaping and warm air from entering, which helps to maintain a consistent temperature.

Durability and Strength

Cold room doors are subjected to various stresses, from heavy traffic and frequent use to harsh environmental conditions. A durable and robust door will withstand these conditions without compromising its insulating properties. At Isoflex, we design our cold room doors to be not only highly functional but also durable enough to handle the demands of daily use. Our products are built to last, with high-strength materials and rigorous testing processes ensuring long-term performance.

Minimized Air Exchange

When a door is opened, there is always a momentary exchange of air between the cold room and the external environment. The design of cold room doors plays a crucial role in minimizing this exchange. Our doors feature advanced designs such as air-tight seals, efficient door closer mechanisms, and well-thought-out door dimensions to minimize the impact of air exchange during regular operations. This design reduces the frequency of temperature fluctuations and helps maintain a stable environment inside the cold room.

The Role of Cold Room Doors in Energy Efficiency

Energy efficiency is a significant consideration for any cold storage facility. Efficient cold room doors can lead to substantial savings in energy costs over time. By providing excellent insulation, effective sealing, and durability, cold room doors help reduce the workload on cooling systems. This not only lowers energy bills but also extends the lifespan of cooling equipment, making cold room doors a key element in a facility’s overall energy management strategy.

At Isoflex, we are dedicated to offering cold room doors that contribute to energy efficiency. Our products are designed to meet or exceed industry standards for thermal insulation and sealing, ensuring that your storage facility operates as efficiently as possible.

Why Choose Isoflex as Your Cold Room Doors Manufacturers?

As an experienced Cold Room Doors Manufacturers, Isoflex stands out for several reasons:

Expertise and Innovation

With years of experience in the cold storage industry, Isoflex combines expertise with innovation. We stay at the forefront of technological advancements to offer products that incorporate the latest in insulation technology, design innovation, and energy efficiency. Our team of experts is constantly researching and developing new solutions to meet the evolving needs of the industry.

Quality Assurance

Quality is at the heart of what we do at Isoflex. We adhere to strict quality control measures throughout the manufacturing process to ensure that every door we produce meets the highest standards. Our commitment to quality means that you can trust our products to deliver consistent performance and durability.

Customized Solutions

We understand that every storage facility is unique, and we offer customized solutions to meet specific needs. Whether you require standard cold room doors or specialized products for unique applications, our team is here to help. We work closely with our clients to understand their requirements and provide tailored solutions that deliver optimal results.

Comprehensive Support

At Isoflex, our relationship with our clients doesn’t end with the sale. We offer comprehensive support services, including installation guidance, maintenance advice, and after-sales support. Our goal is to ensure that you get the most out of your cold room doors and that your storage facility operates smoothly and efficiently.

Real-World Applications of Cold Room Doors

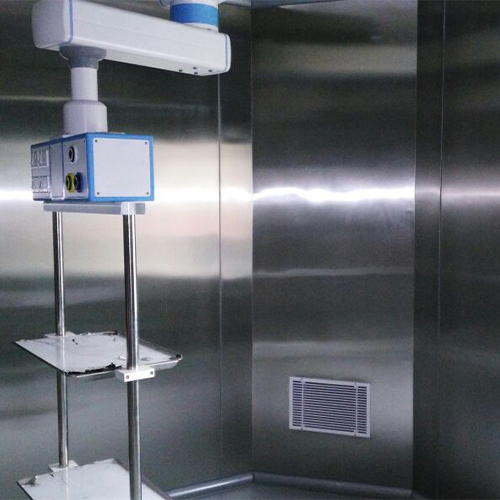

Cold room doors are used in a wide range of applications, from food storage and pharmaceuticals to industrial processes and scientific research. Each application requires specific features and performance criteria, and at Isoflex, we provide products designed to meet these diverse needs.

For example:

- Food Storage: In food storage facilities, cold room doors must maintain the correct temperature to ensure food safety and quality. Our doors are designed to meet stringent hygiene standards and ensure that perishable goods are kept at the right temperature.

- Pharmaceuticals: The pharmaceutical industry requires precise temperature control to ensure the efficacy of medications and vaccines. Our cold room doors help maintain the strict temperature conditions necessary for pharmaceutical storage.

- Industrial Processes: In various industrial processes, cold room doors are used to manage temperature-sensitive materials. Our doors offer reliable performance and durability for these demanding applications.

- Scientific Research: Research laboratories often require controlled environments for experiments and storage. Isoflex provides cold room doors that support the precise temperature conditions needed for scientific research.

Conclusion

Cold room doors are much more than just barriers between spaces; they are essential components that help maintain consistent temperatures, ensure energy efficiency, and support various applications in the cold storage industry. At Isoflex, we take pride in being leading Cold Room Doors Manufacturers, offering high-quality products designed to meet the highest standards of performance and reliability.

By focusing on advanced insulation technologies, effective sealing solutions, and durable construction, our cold room doors help storage facilities maintain the stability of their internal environments, reduce energy costs, and extend the lifespan of their cooling systems.