Essential Features of High-Quality Clean Room Doors: A Guide from Clean Room Doors Manufacturers

Introduction

In the world of high-tech manufacturing and laboratory environments, the role of clean room doors is indispensable. These doors facilitate access and maintain the stringent standards required for controlled environments. As a leading industry player, Isoflex understands the critical importance of these components. In this blog post, we will explore the essential features of high-quality clean room doors and why partnering with top Clean Room Doors Manufacturers like us ensures you get the best solutions for your cleanroom needs.

Air Tightness

One of the primary functions of clean room doors is to ensure air tightness to maintain a controlled environment. High-quality clean room doors from reputable Clean Room Doors Manufacturers are designed with precision to offer exceptional air tightness. This feature helps in controlling temperature, humidity, and particulate contamination levels, which are critical for maintaining the integrity of your clean room.

At Isoflex, we use advanced sealing technologies and high-quality materials to produce doors that create a secure barrier against air leaks. Our doors have robust seals and gaskets that ensure minimal air exchange between clean and non-clean areas.

Durability and Strength

Clean room doors must withstand the rigours of daily operations in high-traffic environments. High-quality, clean room doors should be durable enough to resist physical damage, wear and tear, and frequent use without compromising performance.

Isoflex takes pride in our robust construction techniques that ensure the longevity of our clean room doors. We use durable materials like stainless steel and specialized coatings that enhance the strength of our doors while also making them resistant to corrosion and chemical exposure.

Ease of Cleaning and Maintenance

Clean room doors must be easy to clean and maintain to ensure they do not become a source of contamination. High-quality doors are designed with smooth surfaces, minimal crevices, and easy-to-clean materials.

Isoflex’s clean room doors are engineered for easy maintenance. We use materials and finishes that are resistant to stains and easy to wipe down. Additionally, our doors are designed for straightforward assembly and disassembly, facilitating quick maintenance and ensuring that your clean room environment remains optimal.

Compliance with Industry Standards

Clean room doors must comply with various industry standards and regulations to ensure that they meet the required specifications. High-quality clean room doors are manufactured following international standards such as ISO 14644 and GMP guidelines.

At Isoflex, we adhere to stringent quality control processes and ensure our doors comply with relevant industry standards. Our clean room doors are tested for performance and certified to meet the highest cleanliness and safety standards.

Customizability

Every clean room has unique requirements based on its specific use case. High-quality clean room doors should be customizable to fit various sizes, configurations, and special needs.

Isoflex offers a wide range of customizable options for clean room doors. Whether you need specific dimensions, specialized features like interlocking mechanisms, or unique finishes, our team can deliver tailored solutions that meet your specifications.

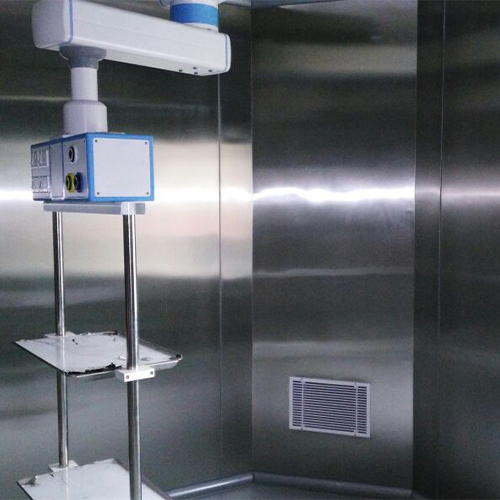

Advanced Technology Integration

Modern, clean room environments often require advanced technological solutions for enhanced functionality. High-quality clean room doors can integrate with automated systems, such as electronic access controls, sensor systems, and door openers.

Isoflex stays at the forefront of technology by integrating advanced features into our clean room doors. Our doors can be equipped with state-of-the-art access control systems, including keycard readers, biometric scanners, and automatic opening mechanisms to enhance security and convenience.

Effective Noise and Vibration Reduction

Reducing noise and vibration is crucial for maintaining a controlled environment in many clean room applications. High-quality clean room doors are designed to minimize these disturbances.

Isoflex’s clean room doors feature advanced noise and vibration dampening technologies. We use specialized materials and design techniques to ensure that our doors contribute to a quieter, more stable, clean room environment.

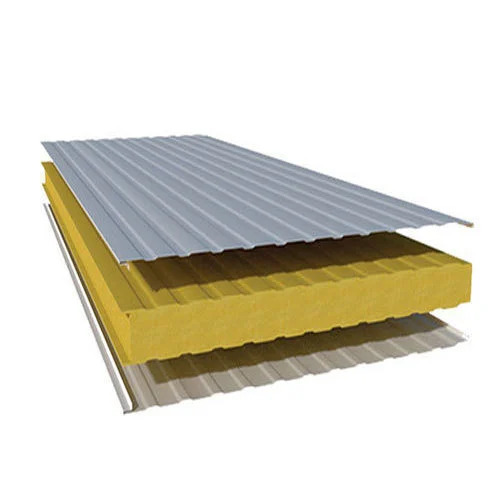

Energy Efficiency

Energy efficiency is important for clean room operations, as energy costs can be significant. High-quality clean room doors are designed to improve energy efficiency by minimizing heat transfer and maintaining consistent environmental conditions.

At Isoflex, our clean room doors are built to be energy-efficient, helping you reduce operational costs and maintain the desired conditions within your clean room. Our designs include thermal insulation features and advanced sealing technologies to improve energy efficiency.

Why Choose Isoflex as Your Clean Room Doors Manufacturers?

When it comes to choosing Clean Room Doors Manufacturers, Isoflex stands out for several reasons:

- Expertise and Experience: With years of industry experience, we understand the complexities of clean room environments and offer products that meet the highest standards.

- Innovative Solutions: We invest in research and development to bring you the latest technologies and innovations in clean room door design and functionality.

- Commitment to Quality: We are dedicated to delivering products that meet and exceed industry standards. Our clean room doors are rigorously tested to ensure superior performance.

- Customer-Centric Approach: We prioritize your needs and work closely with you to provide customized solutions that meet your cleanroom requirements.

- Comprehensive Support: From the initial consultation to post-installation support, Isoflex offers a full range of services to ensure that your cleanroom doors perform optimally throughout their lifecycle.

Conclusion

High-quality clean room doors are essential for maintaining the integrity and functionality of your clean room environment. Key features like air tightness, durability, ease of cleaning, and compliance with industry standards are crucial for effective clean room management.

At Isoflex, we are dedicated to being one of the leading Clean Room Doors Manufacturers by offering products that excel in these essential features. Our commitment to quality, innovation, and customer satisfaction ensures you receive clean room doors that meet your highest standards and operational needs.

If you’re looking for top-notch clean room doors, look no further than Isoflex. Contact us today to learn more about our products and how we can help you achieve your clean room goals.