The Benefits of Using Reputable Cold Room Doors Manufacturer

In today’s ever-evolving industrial landscape, cold room facilities have become indispensable to various industries. These specialized environments preserve the integrity of temperature-sensitive goods, ranging from perishable food items to life-saving pharmaceuticals and precision-engineered chemicals. In the intricate web of factors that make these facilities function, one element stands out as fundamental: cold room doors. These doors are not just physical barriers; they are the guardians of controlled environments, the sentinels that ensure the stability and safety of the precious contents.

The selection of cold room doors is a critical decision that resonates far beyond the threshold of any cold storage room. It is a choice that can define the success, safety, and sustainability of your operations. At Isoflex, we understand the pivotal role that cold room doors play, and we are committed to elucidating the myriad advantages of choosing a reputable manufacturer. This article explores how these doors, sourced from trusted Cold Room doors manufacturers like Isoflex, can revolutionize how your business approaches cold storage, ensuring operational efficiency and product integrity.

The Role of Cold Room Doors

Before diving into the benefits of choosing cold room doors from a reputable manufacturer, let’s briefly understand the importance of these doors in various industries:

Temperature Control

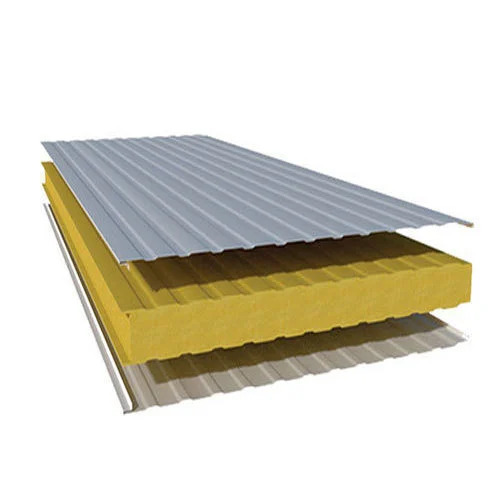

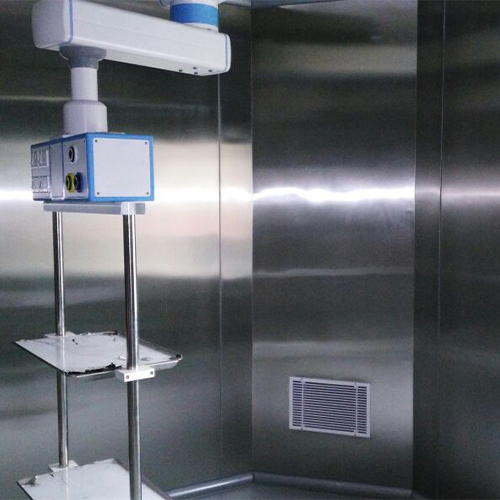

Cold room doors are pivotal in maintaining the desired temperature within cold storage facilities. They create a thermal barrier, preventing heat transfer from the outside environment and helping preserve the stored products’ integrity.

Energy Efficiency

Well-designed cold room doors contribute to energy efficiency by reducing temperature fluctuations. This, in turn, leads to lower energy consumption and operational costs.

Product Safety

In industries such as food storage and pharmaceuticals, product safety is paramount. Cold room doors help maintain the required temperature range, ensuring products remain safe for consumption or use.

Environmental Compliance

Cold room doors are essential for complying with environmental regulations, particularly in industries that deal with temperature-sensitive substances. Proper insulation and sealing are critical to prevent refrigerant leakage and minimize environmental impact.

The Advantages of Choosing Reputable Cold Room doors manufacturers

Now that we understand the importance of cold room doors, let’s explore the benefits of sourcing these doors from reputable manufacturers like Isoflex.

Quality Assurance

Reputable Cold Room doors manufacturers prioritize quality control throughout the production process. Isoflex, as a renowned manufacturer, adheres to stringent quality standards to ensure that every door we produce meets or exceeds industry expectations.

Customization Options

When you choose a reputable manufacturer like Isoflex, you can access various customization options. Our team can tailor cold room doors to your specific requirements, whether size, insulation type, or design.

Durability and Longevity

Cold room doors from reputable manufacturers are built to last. They are constructed using high-quality materials and are designed to withstand the rigours of daily use. Isoflex, in particular, takes pride in offering durable cold room doors that require minimal maintenance.

Energy Efficiency

Energy-efficient cold room doors can significantly impact your operational costs. Reputable manufacturers like Isoflex invest in research and development to create doors with superior insulation properties, reducing energy consumption and environmental impact.

Compliance and Safety

Many sectors place a high priority on regulatory compliance. Cold room doors from reputable manufacturers are designed to meet industry standards and safety regulations. Isoflex is committed to ensuring our doors adhere to all safety and environmental guidelines.

Technical Support and Maintenance

Choosing a reputable manufacturer also means access to excellent technical support and maintenance services. Isoflex offers comprehensive support throughout the lifecycle of your cold room doors, from installation to routine maintenance and repairs.

Isoflex – Your Trusted Cold Room Door Manufacturer

Our Commitment to Excellence

Isoflex has established itself as a leading cold room door manufacturer with an excellent reputation. We stand out in the sector thanks to our dedication to quality, innovation, and client happiness.

Industry Expertise

With years of experience in the field, Isoflex understands the unique requirements of various industries, including food processing, pharmaceuticals, and chemical manufacturing. Our team of experts is well-equipped to provide tailored solutions to meet your specific needs.

Cutting-Edge Technology

Isoflex continually invests in cutting-edge technology to stay at the forefront of cold room door innovation. Our doors are designed to maximize energy efficiency, minimize temperature fluctuations, and ensure the safety of your products.

Sustainable Practices

Environmental responsibility is a core value at Isoflex. We prioritize sustainable manufacturing processes and materials, contributing to a greener future while helping you meet your sustainability goals.

Comprehensive Services

Isoflex offers various services beyond manufacturing, including installation, maintenance, and technical support. We are dedicated to providing a seamless experience for our clients, from the initial consultation to ongoing support.

Conclusion

In conclusion, the benefits of choosing cold room doors from reputable Cold Room doors manufacturers like Isoflex are clear and compelling. Our commitment to quality, customization, durability, energy efficiency, compliance, and exceptional customer service makes us the ideal partner for your cold room door needs. By selecting Isoflex as your cold room door manufacturer, you are ensuring the reliability and efficiency of your cold storage facilities and investing in the future of your business.

As we look ahead, it’s essential to emphasize the long-term impact of your choice. Isoflex doesn’t just provide cold room doors; we offer a pathway to success. By opting for our doors, you safeguard your products, reduce operational costs, and bolster your environmental credentials. Our doors are a testament to sustainability, innovation, and reliability, which will continue to benefit your business for years.

In a world where excellence and trust matter more than ever, Isoflex is a beacon of quality and dedication. We invite you to join the countless satisfied clients who have experienced the Isoflex advantage. If you’re ready to embark on a journey of enhanced efficiency, reduced energy consumption, and unmatched product safety, contact us today for a consultation. Discover how our expertise and unwavering commitment to excellence can elevate your cold storage operations. Trust Isoflex, your partner in cold room door solutions, to open the door to a brighter future for your business.