Combination of PUF and

rockwool panels

The refrigeration industry has evolved with time. It embraced technologies that can increase its efficiency and capability. PUF and Rockwool sandwich panels have become a crucial part of the refrigeration industry due to their insulation properties.

The strength and durability of the PUF Sandwich Panels resulted in a steady increase in market demand, thereby replacing archaic construction and insulation methods. The composite structure of galvanized lamination and insulation material enhanced the structural strength of the PUF Sandwich Panels. Apart from reasonable cold storage solutions, PUF Sandwich Panels have widespread applications in building prefabricated buildings and homes. Also, for building roofs and walls with industrial and domestic insulation requirements. The PUF Sandwich Panels are manufactured using a high-pressure foaming machine with a standard density range of 40 ± 2 kg/m³. The PUF Sandwich Panels are safe with a cam lock, tongue, and groove locking mechanism.

In this regard, it must be mentioned that Rockwool insulated products, too, gained considerable prominence due to their insulation properties. The Rockwool products manufactured by Isoflex consist of Rockwool Sandwich Panels, Rockwool Insulated Doors, etc. They are typically used for high-temperature applications and fire-proof insulation requirements like boiler rooms, industrial kitchens, Environmental chambers, Clean Zones, and Classified Clean Rooms.

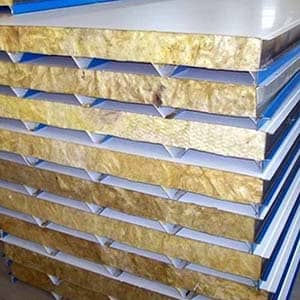

The Rockwool contains rock-based mineral fiber insulation composed of basalt rock and recycled slag. This recycled slag is prepared by melting steel and copper together to liquefy and roll them in fiber form. This insulation is then transformed into slabs and laminated with metals to add durability. The Rockwool Sandwich Panels are made of fire-retardant material with a specialized adhesion process that can withstand temperatures up to 250 degrees Celsius. Since the insulation is tolerant to high temperatures and hence, can host hot water pipes and hot gas exhaust pipes that machines in the boiler room or furnaces produce. Since they are composed of hazard-free and combustible materials, they are actively used in high-temperature and critical applications.

Isoflex is one of the leading environment-friendly PUF and Rockwool sandwich panel manufacturers. Due to a highly efficient and customizable manufacturing unit, the end-products designed by Isoflex in the field of PUF and Rockwool sandwich panels are intelligent, sustainable, and consistent in their design and reliable with their quality.

Combination panels are increasing in demand in addition to the usage of individual PUF sandwich panels, Rockwool sandwich panels, and rock wool insulated doors. The combination panels are made up of PUF as well as Rockwool insulation. This product is one of Isoflex’s niche offerings where both materials are combined to create a robust solution for the insulation purpose. The combination panels are typically used for industrial purposes in building environmental chambers for testing purposes, wherein the required temperature could range between 40 to 180 degrees.

Following are the advantages of using combination panels

- Improvement of energy and thermal efficiency

- Perfect to create sound-proof enclosures

- Support environment chambers with high-temperature resistance.

- Increase heat resistance

- Durable and easy installation

- Customizable design with supporting infrastructure and ancillaries

- Anti-corrosive property

- High-quality thermal insulation with precision

The advanced technology in building these durable and lightweight combination panels makes them perfect for the following application areas.

- Green building initiative

- Safety solution from fire hazards

- Acoustic requirement

- Food and beverage industry

- Pharma clean room

- Automobile and electronic units

Recent Projects